AI-Driven Plunger Lift Automation for Gas Well Optimization

How we helped an Oil & Gas company transform manual 24/7 plunger operations into intelligent automated control, increasing gas production by 10% across 200+ wells while preventing costly shutdowns.

Project Overview

Key Results & Impact

10% increase in monthly gas barrel production

200+ wells now under automated control

24/7 manual monitoring eliminated

Significant reduction in unplanned well shutdowns

Proactive High Line Pressure event management

6+ years of continuous operation and refinement

What if your best, most experienced field operator could personally monitor every single one of your wells, 24 hours a day, and make perfect, tiny adjustments every few cycles? What would that be worth?

For one of our clients, this wasn’t a thought experiment—it was a $100+ million-dollar question.

They were managing hundreds of plunger lift gas wells, and the entire operation was a 24/7, manual firefight.

The Challenge: “Gut Feel” Operations Can’t Scale

The client’s system was entirely reactive. Operators, relying on hard-won intuition and experience, drove from well to well, continuously making manual adjustments to plunger systems.

This created a host of massive challenges:

- Inconsistent Performance: The production of a well depended entirely on which operator was on shift. An expert’s “gut feel” was good, but it wasn’t a scalable, scientific, or consistent way to run a 200-well operation.

- Constant Firefighting: Operators could only respond to problems after they happened. An unexpected High Line Pressure (HLP) event would shut down a well, costing significant production time (and money) before someone could even get on-site.

- Wasted Resources: The company was spending enormous operational overhead just to have people available 24/7 for these routine, manual adjustments.

They needed to move from a reactive, manual system to a proactive, intelligent one. But they couldn’t just “flip a switch” to full automation—they needed to maintain complete supervisory control and safety.

The Solution: An AI-Driven System That Learns and Adapts

We partnered with them to design and build a comprehensive, AI-driven automation system that acts as an intelligent “co-pilot” for their operations team.

This wasn’t just simple scripting. We built a true learning system.

- We Taught the AI What “Perfect” Looks Like: We started by feeding custom machine learning models years of their historical SCADA data. The AI learned to identify the ideal velocity range for every single well, accounting for plunger type, well characteristics, pressure, and even seasonal changes.

- We Built an “Always-On” Controller: The new system integrates directly with their existing SCADA infrastructure. It constantly watches, and after every 2-3 plunger cycles, it analyzes the performance.

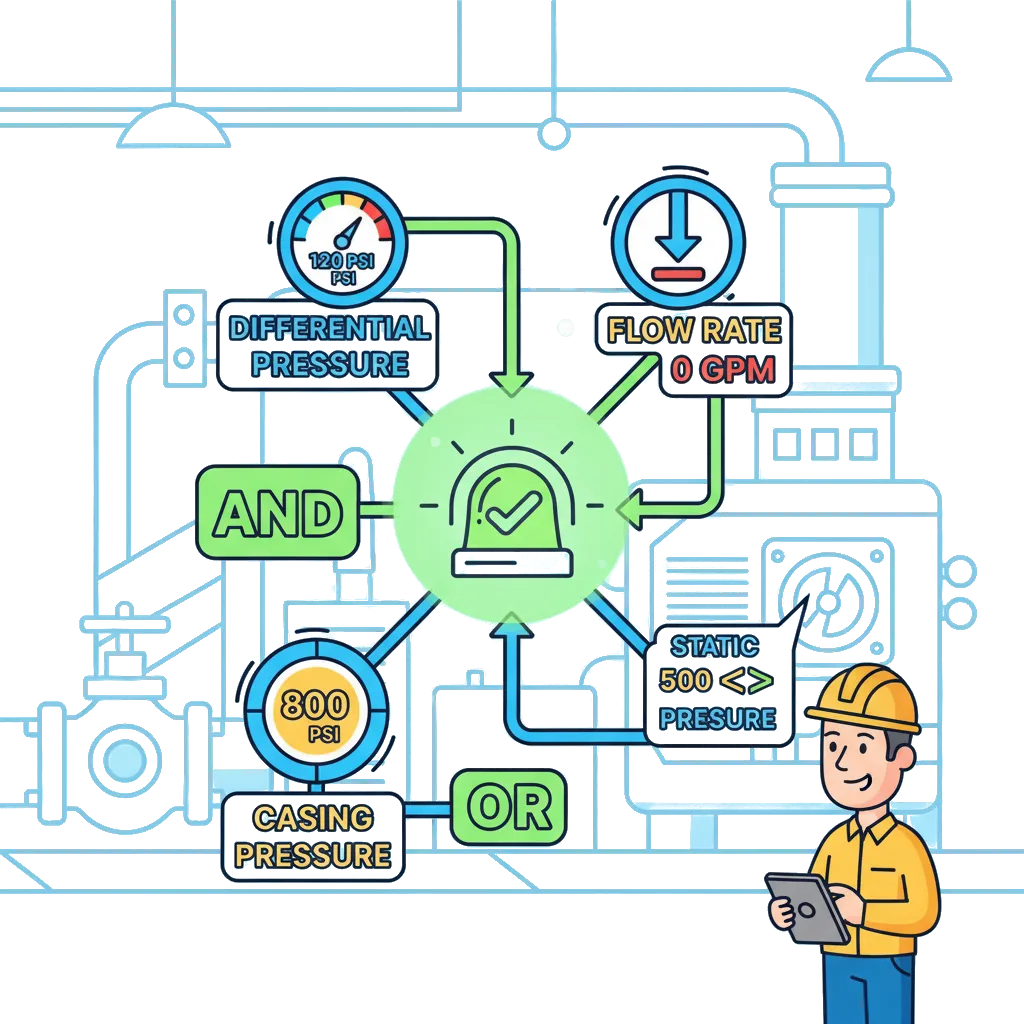

- It Makes Micro-Adjustments: Based on the AI model, the controller automatically adjusts three key variables—Shut-in Time, Max After Flow, and Critical Flow—to nudge the well back into its perfect, AI-determined velocity range.

Crucially, this system was built for Human-AI Collaboration, not replacement. Supervisors maintain 100% control.

- They Set the Boundaries: Supervisors define the min/max safety limits for all parameters.

- The AI Makes Suggestions: If the “perfect” setting is outside the pre-set limits, the system doesn’t make the change. It generates a recommendation for the supervisor to approve.

- Humans Have the Final Say: A manual override is available at any time, giving the team complete confidence and control.

Finally, the system is smart about risk. It recognizes the conditions that lead to High Line Pressure events and proactively shifts its strategy to prevent the well from shutting down in the first place.

The Results: 6+ Years of Compounding Success

We started with a 10-well pilot. After its immediate success, we scaled the system across 200+ wells.

This system has been in continuous, reliable operation for over six years, and the results are staggering:

- A 10% Monthly Production Increase: By consistently keeping wells in their optimal range, the system delivered a massive, sustained boost in gas production.

- Operational Efficiency Skyrocketed: The 24/7 manual monitoring was eliminated. Operators were freed from a cycle of reactive firefighting and could now focus on higher-value supervisory and maintenance tasks.

- Costly Shutdowns Were Prevented: The intelligent HLP management drastically reduced unplanned shutdowns, protecting equipment and maximizing uptime.

- A System That Gets Smarter: The AI models are periodically retrained with new data, meaning the system has continued to adapt and improve over its 6+ year lifespan.

This project is a perfect demonstration of our philosophy: by thoughtfully implementing AI as a tool to enhance human expertise, we can deliver transformative, long-term value that is safe, scalable, and incredibly profitable.

Interested in Similar Results?

Let's discuss how we can create a custom solution that delivers similar impact for your business.

Start Your ProjectRelated Case Studies

From Legacy to Modern: Streamlining Oil & Gas Operations

How We Saved a Client $200k Annually by Replacing a "Good Enough" Legacy System

Beyond the Threshold

How we transformed a threshold-based SCADA alarm system into an intelligent, contextual smart alarm platform that cuts noise and accelerates action.