From Legacy to Modern: Streamlining Oil & Gas Operations

How We Saved a Client $200k Annually by Replacing a "Good Enough" Legacy System

Project Overview

Key Results & Impact

Saved $200,000 annually in labor costs

Improved data quality to 100% with standardized fields

Centralized operator workflows for increased efficiency

Provided a foundation for predictive AI models

In business, one of the most expensive phrases you’ll hear is: “We’ve always done it that way.”

Often, legacy systems—those old, clunky, manual-entry platforms—aren’t “broken” enough to be replaced, but they are silently costing companies a fortune in lost productivity and bad data.

We partnered with a client to tackle one such system, and the results highlight the massive value of building smart, integrated web applications.

The Challenge: “Death by a Thousand Clicks”

Our client was using a legacy system for a critical daily task: tracking production downtime.

Every day, operators across 32 different routes had to log into this system and manually fill out an enormous, complex form for any well that didn’t meet its production target.

This process was a drain on time and a disaster for data quality.

- Massive Time Sink: Operators were spending over a combined 16 hours every single day just on this one piece of paperwork.

- Redundant Data Entry: The form forced operators to manually re-enter information the system should have already known, like their Route, Pad, and Well number.

- Poor Data Quality: The system used free-text fields for “downtime codes.” This meant operators would enter “Subsurface Problem,” “Sub-Surface,” “subsfc,” or “Downhole Obstruction” for the same issue. Typos were rampant.

- No Reporting: With such “dirty” data, it was nearly impossible for management to run accurate reports to identify and fix recurring problems.

- System-Hopping: This was yet another system operators had to log into, fragmenting their workflow and forcing them to juggle different logins and interfaces.

The Solution: An Intelligent, Integrated Production Task System

We didn’t just rebuild the old form. We completely re-imagined the workflow by focusing on automation and integration.

We built a new web application that completely replaced the old system.

- Automatic SCADA Integration: The new system automatically connects to SCADA at the end of each day to review the previous day’s gas and water production volumes.

- Smart Task Generation: It compares that production against a target (which management can configure). If a well underperforms (e.g., < 80% of target), the system automatically generates a task in the same centralized task system the operators already use for their other work.

- A Simplified, Powerful UI: The operator is no longer presented with a giant, blank form. They get a simple task. All they have to do is select the correct downtime code from a standardized, pre-defined list and add a brief comment. All the information about the Route, Pad, and Well is already attached.

- “Carry Forward” Feature: For long-term issues (like a well being shut-in for maintenance), operators can now “carry forward” a code, saving them from having to enter the same report day after day.

The Results: More Savings, Better Data, and a Foundation for AI

The impact was immediate and profound.

- Massive Cost Savings: By eliminating 16 hours of daily paperwork, we saved the client an estimated $200,000 USD per year in labor costs alone. This doesn’t even include the (now eliminated) licensing costs for the old platform.

- 100% Data Quality: By replacing free-text fields with standardized dropdowns, the client’s downtime data went from “messy and unusable” to “perfectly clean and reportable” overnight.

- A Truly Centralized Workflow: Operators are happier and more efficient. They no longer “system-hop.” All their work, from critical alarms to routine production reports, lives in one place.

- Full Client Control: As a custom solution, the client has full control over features. We have since leveraged this platform countless times to add new efficiencies, further reducing paperwork and improving reporting.

What’s Next: From Clean Data to Predictive Operations

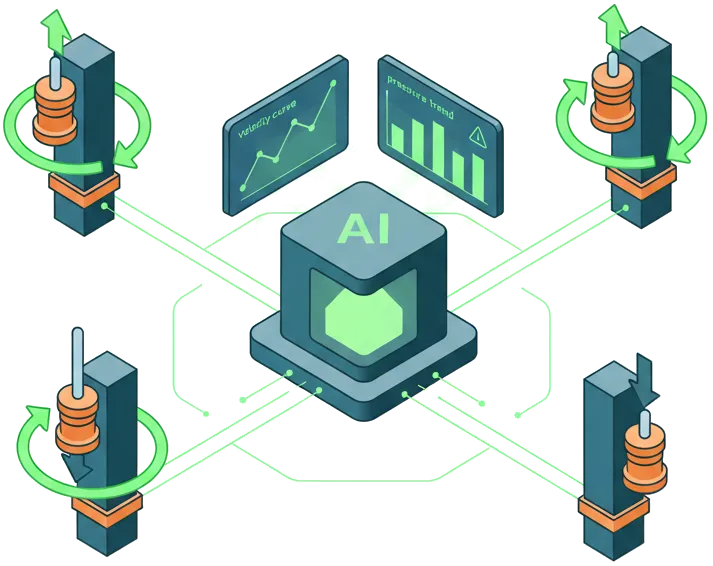

This project didn’t just solve a problem—it created an opportunity. After years of gathering this perfectly clean, structured data, we are now exploring the next phase: Artificial Intelligence.

This high-quality dataset is the perfect fuel for machine learning models. We are now helping our client explore ways to:

- Build Predictive Downtime Models: Analyze patterns to forecast which wells are at the highest risk of downtime before it happens.

- Identify Root Causes: Use AI to find hidden correlations (e.g., “Downtime on Route 5 is 80% more likely after three days of a specific pressure pattern”) that are impossible for a human to spot.

- Optimize Maintenance Schedules: Automatically create proactive maintenance tasks (e.g., “This well’s pattern matches 90% of past pump failures. Dispatch maintenance.”) rather than reacting to failures.

- Enhance Production Targets: Use historical performance data to set more realistic and dynamic production targets.

This is the power of modernization. We didn’t just replace a form; we built a foundation for an intelligent, predictive, and more profitable operation.

Are your teams still battling legacy forms and “system-hopping”? Let’s talk about how we can centralize your workflow and turn your data into your most valuable asset.

Interested in Similar Results?

Let's discuss how we can create a custom solution that delivers similar impact for your business.

Start Your ProjectRelated Case Studies

AI-Driven Plunger Lift Automation for Gas Well Optimization

How we helped an Oil & Gas company transform manual 24/7 plunger operations into intelligent automated control, increasing gas production by 10% across 200+ wells while preventing costly shutdowns.

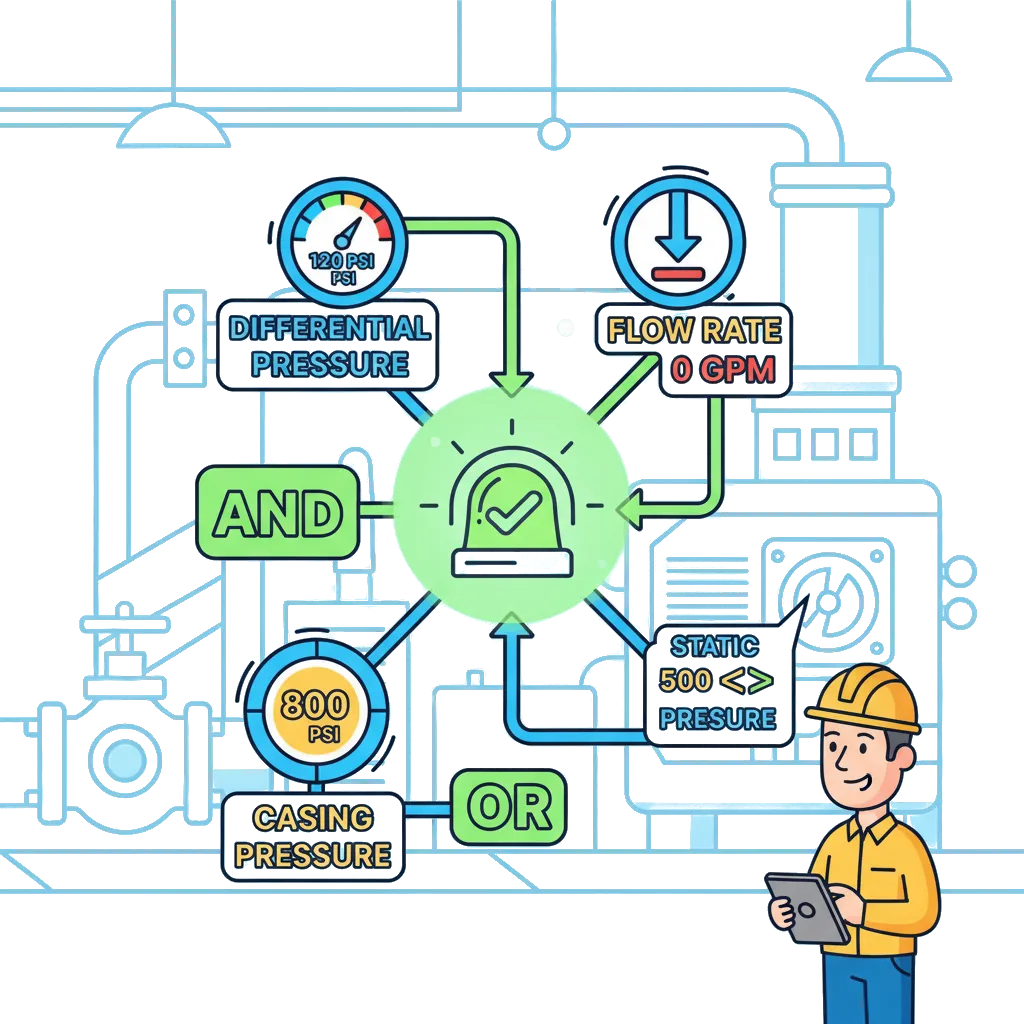

Beyond the Threshold

How we transformed a threshold-based SCADA alarm system into an intelligent, contextual smart alarm platform that cuts noise and accelerates action.